Introduction of Peanut Butter Filling Machine

Peanut butter filling machine adopts compressed air as power, it is a automatic quantitative filling machine that widely used in food, condiment, daily chemical, pharmaceutical, chemical, lubricant and fine chemical industries. Our peanut butter filling machine equipped with high precise pneumatic components and special rotary valve to control the filling and weighing. Besides peanut butter ,it is also used to filling Tahini, sesame butter, sweet sauce, ketchup, jam, cream, milk and other viscous paste product in food industry.

Filling Machine Working Principle

Connect the air source, the knob on the control panel or the foot switch will drive the piston rod of the metering cylinder to perform a series of cyclic movements such as up and down reciprocating motion, suction, filling, etc.,

when the air cylinder drives the metering cylinder to move downward, it will open the valve under the hopper, then metering cylinder suck and filled with peanut butter, the piston moves to the lowest end, the valve will close when the metering cylinder is full.

When the metering cylinder piston moves upward, the nozzle spool sinks and it will start to fill peanut butter in the bottle. The filling will stop when the metering cylinder piston moves to the highest end.

Anti Drip Filling Nozzle

It is made of high quality food grade stainless steel, easy to be replaced and cleaned.

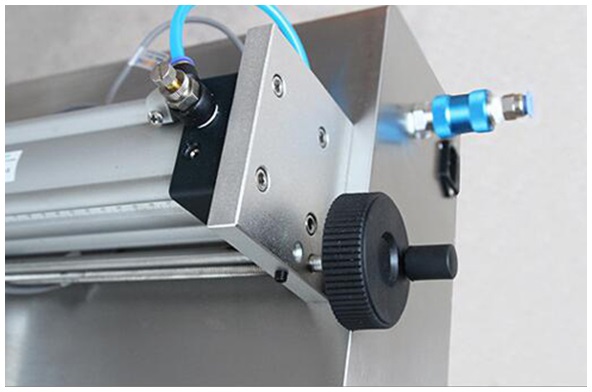

Filling Adjust Wheel

It is allows operator to adjust the filling volume freely.It is very easy to operate.

Durable Air Cylinder

More powerful and efficient.Highly secure, suitable for use in explosion-proof environment.

Three Way Valve

To prevent peanut butter go back, no leaking, easy to remove and wash.

Features of Peanut Butter Filling Machine

- Our peanut butter filling machine adopts a plunger piston, and quantitative filling system adjusts the filling volume and speed with high precision, the measurement accuracy is less than 2%.

- The parts in contact with the peanut butter are made of 316L stainless steel and the piston is made of PTFE material, which meets GMP requirements.

- Semi-automatic piston peanut filling machine supports manual and automatic switching. The filling nozzle can be replaced according to different materials, and it can fill the granular slurry fluid material.

- Equipped with an automatic blender to ensure a thorough mixing of peanut butter.

- Filling bulkhead is anti-drip, anti-drawing and lifting filling device.

- Highly adaptable, quickly adjust and replace bottles for different materials.

- The hopper, stainless steel tee and three-way steering valve are easy to remove and wash.

Peanut Butter Machine Technical Specification

| Model | Filling Volume | Dimension | Weight | |||

|---|---|---|---|---|---|---|

| BF-100 | 5~100 ml | 980*400*390 mm | 460*460*490 mm | 35 kg | ||

| BF-300 | 10~300 ml | 980*400*390 mm | 460*460*490 mm | 36 kg | ||

| BF-500 | 50~500 ml | 980*430*400 mm | 460*460*490 mm | 42 kg | ||

| BF-1000 | 100~1000 ml | 1170*410*380 mm | 460*460*490 mm | 43 kg | ||

| BF-2500 | 300~2500 ml | 1430*400*390 mm | 460*460*550 mm | 45 kg | ||

| BF-5000 | 1000~5000 ml | 1200*480*460 mm | 460*460*550 mm | 53 kg | ||

| Filling Speed | 5~25 Bottles/min | |||||

| Volume Error | <1% | |||||

| Power Supply | AC 220V 50Hz / 110V 60Hz | |||||

| Air Pressure | 1.5Hp air compressor ; 0.4-0.6mpa air pressure | |||||